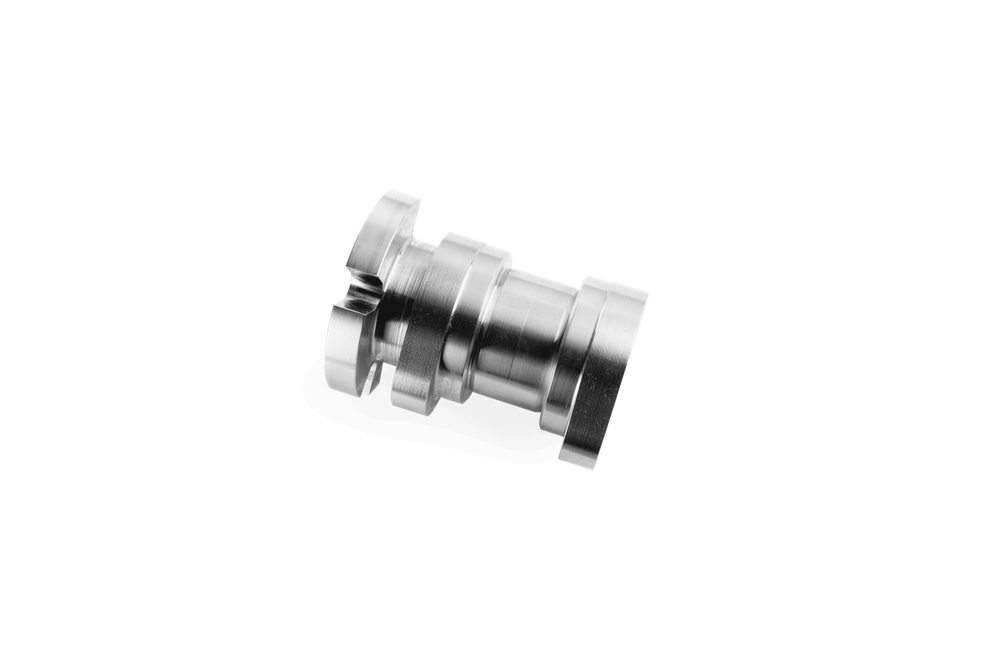

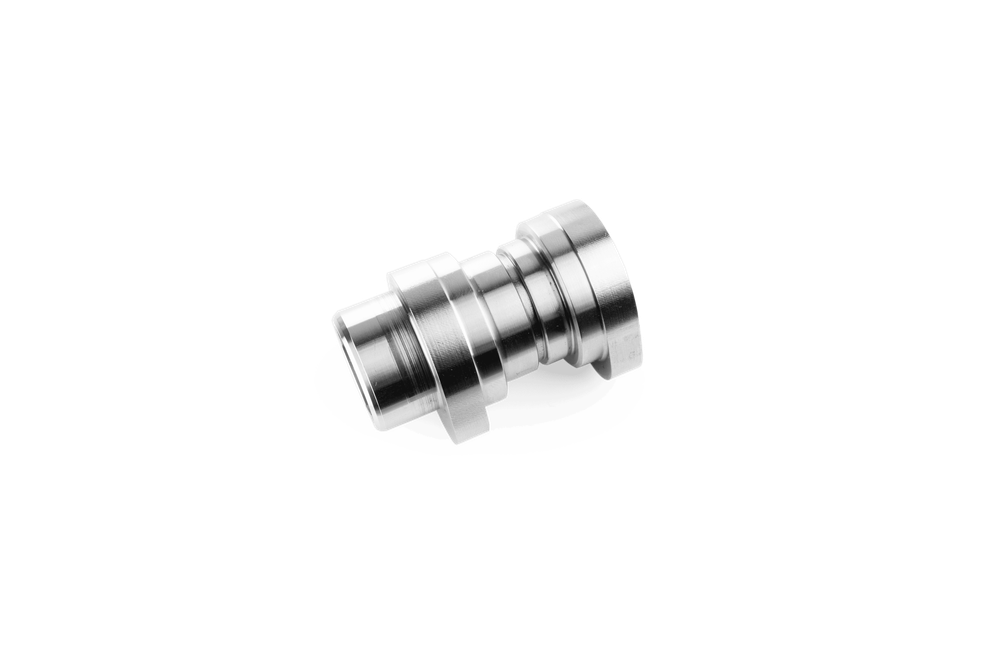

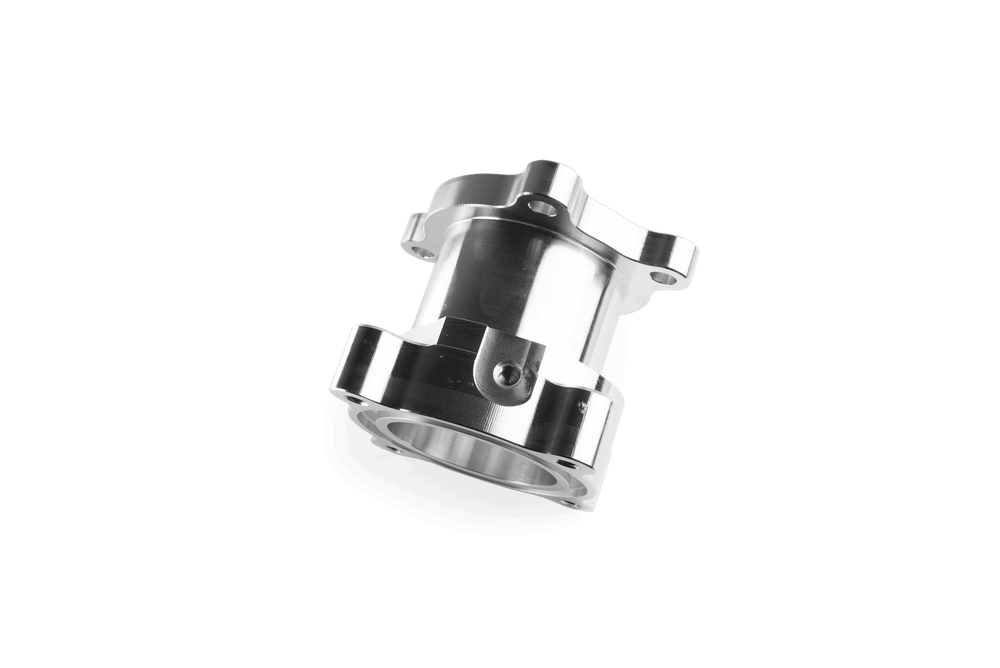

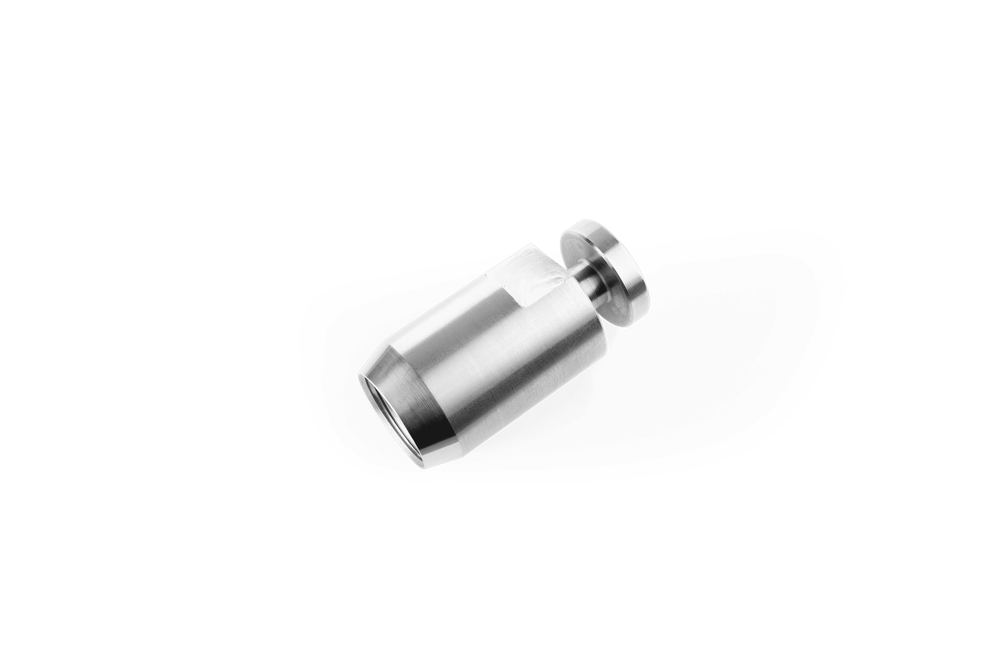

Advanced turning and milling technology for the highest demands

WST - always one turn ahead. As a leading manufacturer of milled and turned parts, we supply the industry with complex, high-quality solutions. But we are not only experts in precision. We are also machine experts, materials professionals, organizational talents and enthusiastic fans of our customers.

Heavy metal - one turn ahead!

Wonderfully versatile: WST produces turned parts from almost all machinable materials. The variety of materials is our strength - that's how we rock production.

Article-specific production lines

Over 30 years of experience and innovation

Reaching boldly for the stars while keeping both feet on the ground - WST is growing continuously and full of innovative spirit. Proven solutions are a solid foundation for truly fresh approaches.

Our history

In use worldwide. Our turned parts are in the thick of it instead of just being there. They are at the heart of high-tech products of all kinds. WST supplies precision-milled and turned parts to sectors including automotive and transmission systems, medical technology, mechanical engineering, power tools, industrial equipment, construction, and drive technology. Our precision turned parts ensure the optimal functioning of vehicles, machines and devices - from cars to cranes.

Areas of application

WST creates clever solutions with identity and character for many industries: Automotive or transmission construction, drive technology, hydraulics, building services or electronics. As small as the turned parts may be, they make a really big vehicle run. Highly complex inner workings function smoothly with WST parts. Whether automotive or non-automotive - our turned parts are indispensable components for demanding applications.

Valve trains

Trucks / commercial vehicles

Steering systems

E-Bikes

Hydrogen drive

Drive technology

Job offers at WST

Commercial professions

Technical professions

You can rely on it: WST is one revolution ahead.

Do you have any questions? Simply contact us using our form or call us directly. We are here for you!

Hauptsitz

WST Präzisionstechnik GmbH

Gerwigstr. 9

79843 Löffingen

Tel: +49 (7654) 9111-0

Fax: +49 (7654) 9111-440

E-Mail: info@wst-willmann.de

Privacy Preferences

We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), e.g. for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. Here you will find an overview of all cookies used. You can give your consent to entire categories or have further information displayed and thus select only certain cookies.