Special requests? We manufacture exclusive and customized special tools under our own Durhino brand. Our in-house developed solutions combine precision with functionality and can be individually tailored to your specific requirements.

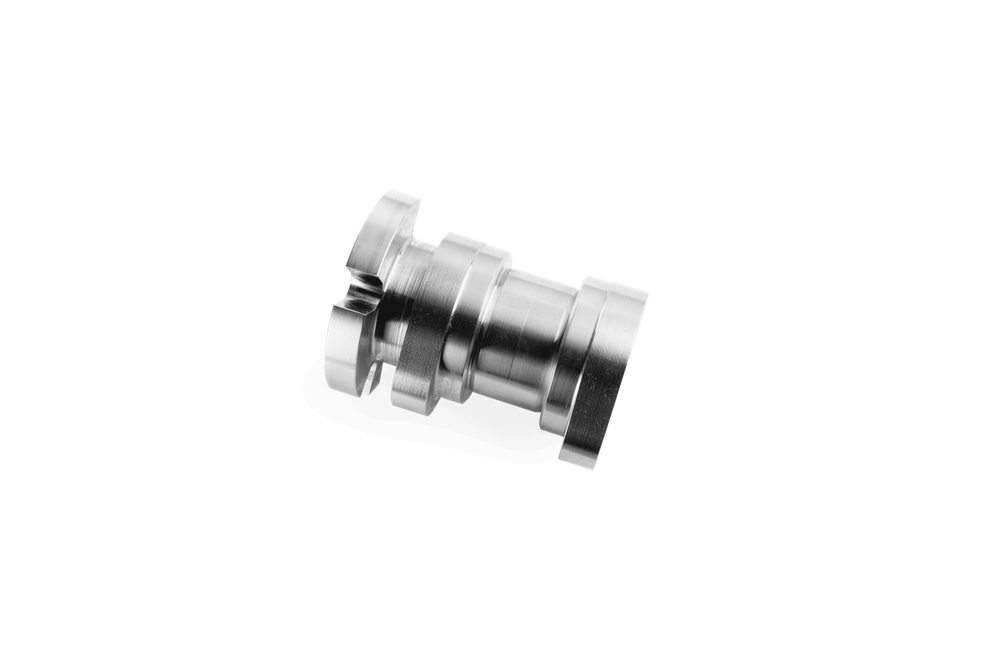

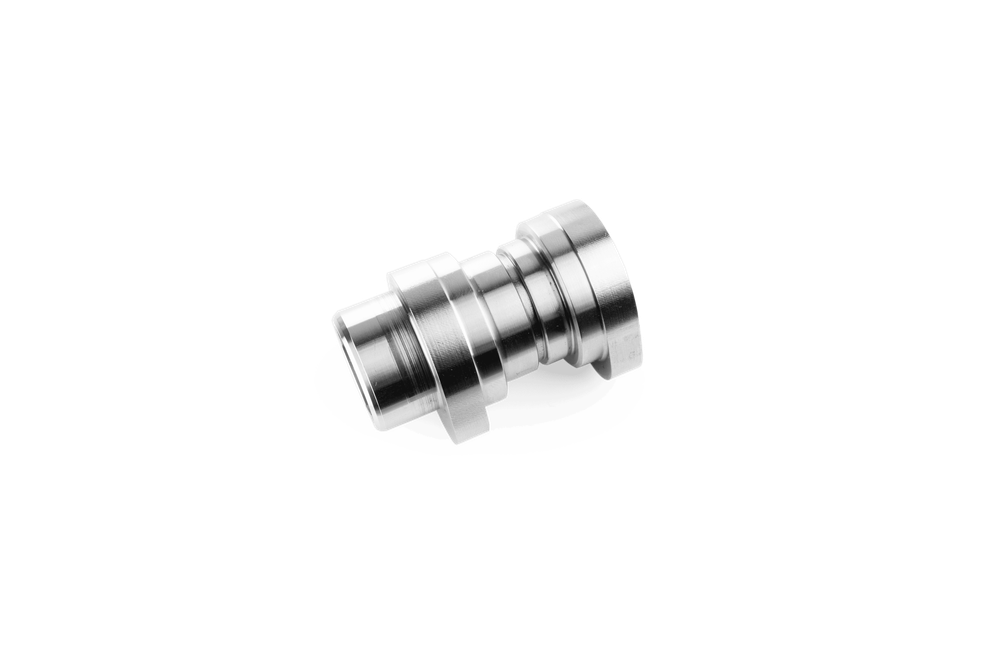

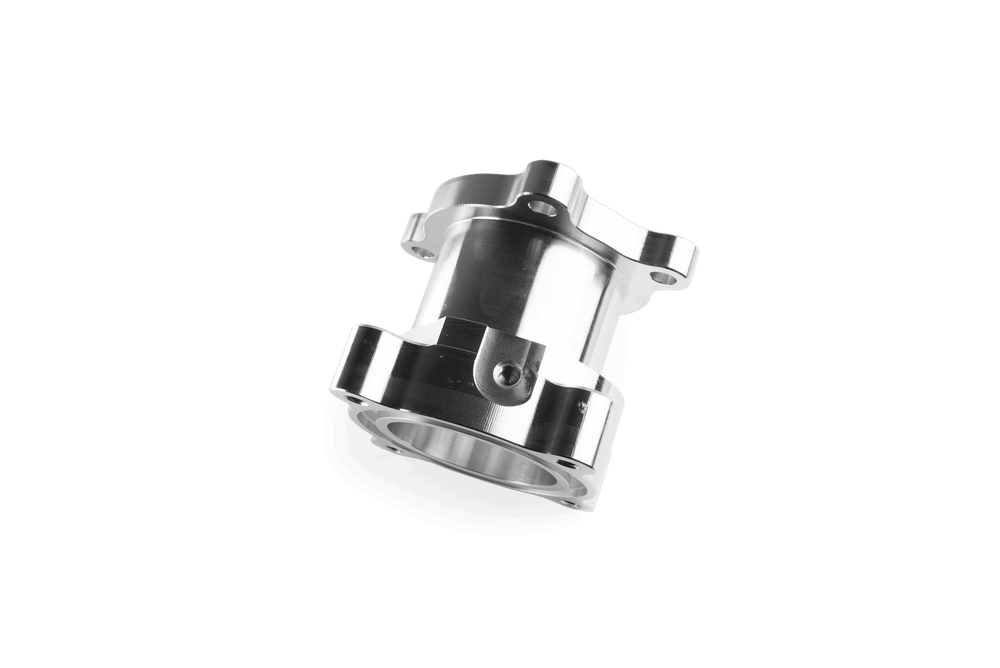

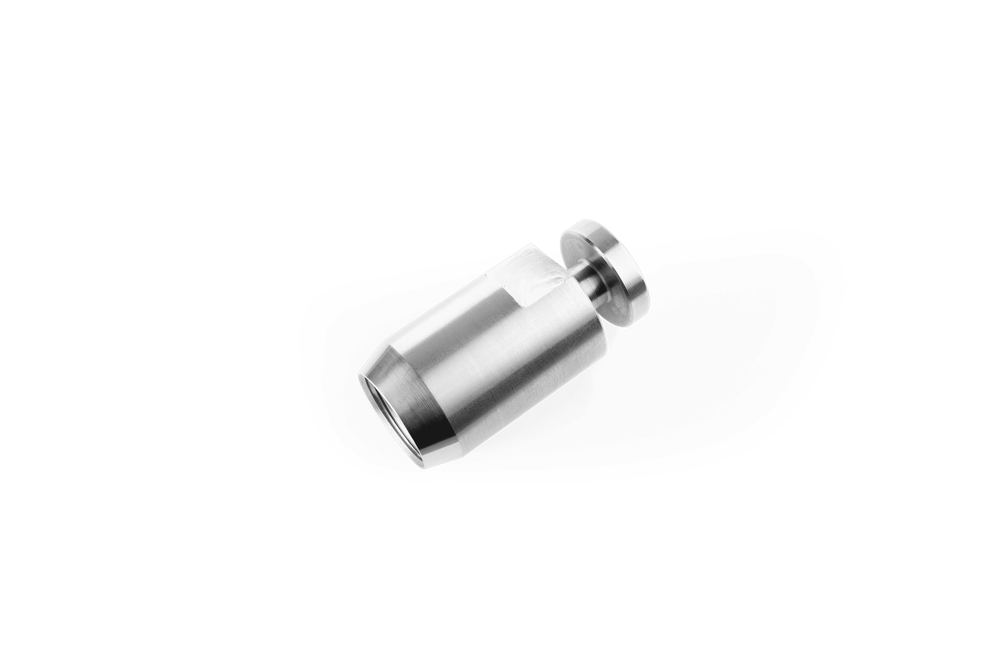

From the Black Forest out into the world. WST supplies milled and turned parts to many industries: Automotive or transmission construction, drive technology, hydraulics, building services or electronics. Our precision turned parts ensure the optimal functioning of vehicles, machines and devices - from cars to cranes.

WST creates clever solutions with identity and character for many industries: Automotive or transmission construction, drive technology, hydraulics, building services or electronics. As small as the turned parts may be, they make a really big vehicle run. Highly complex inner workings function smoothly with WST parts. Whether automotive or non-automotive - our turned parts are indispensable components for demanding applications.

We are at your side with our high-quality machinery. Variation options in two sectors are our specialty:

/ Fast response time

/ Broad processing spectrum

/ Short distances

/ High standardization

/ Development of innovative manufacturing processes

/ High degree of automation

/ Process reliability

/ Solution competence

Of course, we don't stop there and also take on downstream processes such as grinding, honing, embossing, gear cutting and surface and heat treatments of all kinds - just contact us!

Special requests? We manufacture exclusive and customized special tools under our own Durhino brand. Our in-house developed solutions combine precision with functionality and can be individually tailored to your specific requirements.

To turn visions into successful products, WST tests innovative technologies and processes at its in-house process development center. Our customers benefit from this in two ways: the risk of undetected development errors is reduced and the possibility of early, cost-effective intervention increases. All in all, an effect that gives WST and its customers a significant competitive advantage in the market.

The journey of a component begins with an inquiry from our customers, who have specific requirements for the component.

The sales department analyzes the request, advises the customer on suitable solutions and prepares individual offers to best meet the customer's needs.

After handover by the sales department, project management takes over the coordination of the individual steps, always taking the customer's requirements into account.

It draws up a project plan and monitors compliance with the schedule, project costs and quality standards.

Purchasing procures the materials and components required for production.

This includes the selection of reliable suppliers to ensure the quality of the raw materials.

The materials are processed in production.

Specialists operate modern machines to manufacture the components in accordance with the technical specifications.

WST also offers other processing methods such as engraving, milling, broaching, grinding and hardening.

After production, the components undergo a cleaning process.

This is important to remove impurities and ensure the quality of the end product.

The cleaned components are carefully packaged and subjected to a quality check.

This ensures that all specifications are met before the components are dispatched.

Finally, the pre-packed components are delivered to the customer on time, ensuring efficient and safe transportation.

Metal makes the music - and with our variety of materials, we rock production. We process chrome-nickel steels, case-hardening and heat-treatable steels, stainless and acid-resistant steels, tool steels and free-cutting steels. We also process non-ferrous metals such as aluminum, brass and copper. The production range includes diameters from 10 mm to 90 mm from the bar and up to 200 mm in the chuck.

Trust is good, control is better - and we prove both with our certifications. They stand for the highest quality standards and excellent service. We confirm our expertise and reliability through audits. Each award underlines our commitment to excellence and trust - a guarantee for your complete satisfaction.

T +49 (7654) 9111-0

E info@wst-willmann.de

T +49 (7654) 9111-0

E info@wst-willmann.de

T +49 (7654) 9111-0

E info@wst-willmann.de

Gerwigstraße 9

79843 Löffingen

Deutschland

T +49 (7654) 9111-0

F +49 (7654) 9111-440

M info@wst-willmann.de

Hauptsitz

WST Präzisionstechnik GmbH

Gerwigstr. 9

79843 Löffingen

Tel: +49 (7654) 9111-0

Fax: +49 (7654) 9111-440

E-Mail: info@wst-willmann.de

We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), e.g. for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. Here you will find an overview of all cookies used. You can give your consent to entire categories or have further information displayed and thus select only certain cookies.